Page 6 - 2398-Caterpillar_SARL-GB

P. 6

Video:

youtube.com/

watch?v=35E79BVt_5c

Finally, with the machines on site over 2,000

meters up in the Alps, a team of Zeppelin’s

service technicians, all experts in large machines,

set to work modifying and assembling.

One Cat D8T Dozer had a three-tooth rear ripper

added, the other a one-tooth rear ripper. And

they were both fitted with 3.9m wide SU blades

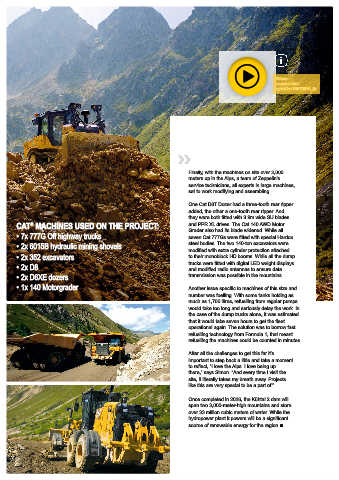

CAT MACHINES USED ON THE PROJECT: and PPR XL drives. The Cat 140 AWD Motor

®

• 7x 777G Off highway trucks Grader also had its blade widened. While all

seven Cat 777Gs were fitted with special Hardox

• 2x 6015B hydraulic mining shovels steel bodies. The two 140-ton excavators were

modified with extra cylinder protection attached

• 2x 352 excavators to their monoblock HD booms. While all the dump

• 2x D8 trucks were fitted with digital LED weight displays

and modified radio antennas to ensure data

• 2x D6XE dozers transmission was possible in the mountains.

• 1x 140 Motorgrader Another issue specific to machines of this size and

number was fuelling. With some tanks holding as

much as 1,700 litres, refuelling from regular pumps

would take too long and seriously delay the work. In

the case of the dump trucks alone, it was estimated

that it would take seven hours to get the fleet

operational again. The solution was to borrow fast

refuelling technology from Formula 1, that meant

refuelling the machines could be counted in minutes.

After all the challenges to get this far it’s

important to step back a little and take a moment

to reflect, “I love the Alps. I love being up

there,” says Simon. “And every time I visit the

site, it literally takes my breath away. Projects

like this are very special to be a part of.”

Once completed in 2026, the Kühtai 2 dam will

span two 3,000-meter-high mountains and store

over 33 million cubic meters of water. While the

hydropower plant it powers will be a significant

source of renewable energy for the region. ■