Page 14 - 2324-Caterpillar_SARL-GB

P. 14

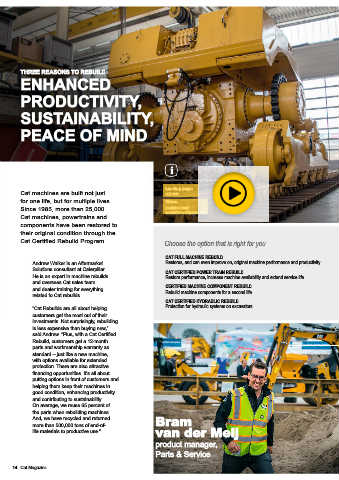

THREE REASONS TO REBUILD

ENHANCED

PRODUCTIVITY,

SUSTAINABILITY,

PEACE OF MIND

i

Landing page:

Cat machines are built not just cat.com

for one life, but for multiple lives. Video:

Since 1985, more than 25,000 youtube.com/

watch?v=w36yHXzTtf0

Cat machines, powertrains and

components have been restored to

their original condition through the

Cat Certified Rebuild Program. Choose the option that is right for you

CAT FULL MACHINE REBUILD

Andrew Walker is an Aftermarket Restores, and can even improve on, original machine performance and productivity.

Solutions consultant at Caterpillar. CAT CERTIFIED POWER TRAIN REBUILD

He is an expert in machine rebuilds Restore performance, increase machine availability and extend service life.

and oversees Cat sales team CERTIFIED MACHINE COMPONENT REBUILD

and dealer training for everything Rebuild machine components for a second life.

related to Cat rebuilds.

CAT CERTIFIED HYDRAULIC REBUILD

“Cat Rebuilds are all about helping Protection for hydraulic systems on excavators.

customers get the most out of their

investments. Not surprisingly, rebuilding

is less expensive than buying new,”

said Andrew. “Plus, with a Cat Certified

Rebuild, customers get a 12-month

parts and workmanship warranty as

standard – just like a new machine,

with options available for extended

protection. There are also attractive

financing opportunities. It’s all about

putting options in front of customers and

helping them keep their machines in

good condition, enhancing productivity

and contributing to sustainability.

On average, we reuse 65 percent of

the parts when rebuilding machines.

And, we have recycled and returned Bram

more than 500,000 tons of end-of-

life materials to productive use.” van der Meij

product manager,

Parts & Service

14 Cat Magazine