Page 26 - 2338-JA_Delmas-GB

P. 26

WESTERN AFRICA

THE 6015B AND 6020B

HYDRAULIC EXCAVATORS

SCORE A STORMING SUCCESS

Between one third and one half of sales of the 6015B and 6020B hydraulic excavators in the EAME zone

have been made by JA Delmas.

Previously made by Bucyrus, these ex-

cavators are now manufactured entirely

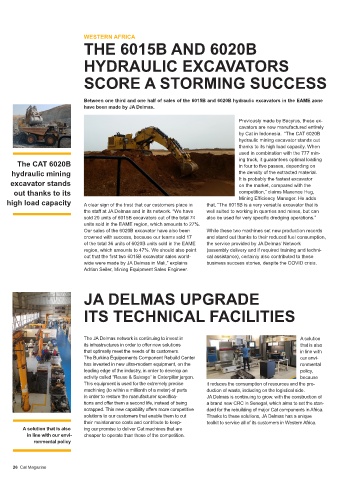

by Cat in Indonesia. “The CAT 6020B

hydraulic mining excavator stands out

thanks to its high load capacity. When

used in combination with the 777 min-

ing truck, it guarantees optimal loading

The CAT 6020B in four to five passes, depending on

hydraulic mining the density of the extracted material.

excavator stands It is probably the fastest excavator

on the market, compared with the

out thanks to its competition,” claims Maxence Hug,

Mining Efficiency Manager. He adds

high load capacity A clear sign of the trust that our customers place in that, “The 6015B is a very versatile excavator that is

the staff at JA Delmas and in its network. “We have well suited to working in quarries and mines, but can

sold 20 units of 6015B excavators out of the total 74 also be used for very specific dredging operations.”

units sold in the EAME region, which amounts to 27%.

Our sales of the 6020B excavator have also been While these two machines set new production records

crowned with success, because our teams sold 17 and stand out thanks to their reduced fuel consumption,

of the total 36 units of 6020B units sold in the EAME the service provided by JA Delmas’ Network

region, which amounts to 47%. We should also point (assembly delivery and if required training and techni-

out that the first two 6015B excavator sales world- cal assistance), certainly also contributed to these

wide were made by JA Delmas in Mali,” explains business success stories, despite the COVID crisis.

Adrian Seiler, Mining Equipment Sales Engineer.

JA DELMAS UPGRADE

ITS TECHNICAL FACILITIES

The JA Delmas network is continuing to invest in A solution

its infrastructures in order to offer new solutions that is also

that optimally meet the needs of its customers. in line with

The Burkina Équipements Component Rebuild Center our envi-

has invested in new ultra-modern equipment, on the ronmental

leading edge of the industry, in order to develop an policy,

activity called “Reuse & Salvage” in Caterpillar jargon. because

This equipment is used for the extremely precise it reduces the consumption of resources and the pro-

machining (to within a millionth of a meter) of parts duction of waste, including on the logistical side.

in order to restore the manufacturer specifica- JA Delmas is continuing to grow, with the construction of

tions and offer them a second life, instead of being a brand new CRC in Senegal, which aims to set the stan-

scrapped. This new capability offers more competitive dard for the rebuilding of major Cat components in Africa.

solutions to our customers that enable them to cut Thanks to these solutions, JA Delmas has a unique

their maintenance costs and contribute to keep- toolkit to service all of its customers in Western Africa.

A solution that is also ing our promise to deliver Cat machines that are

in line with our envi- cheaper to operate than those of the competition.

ronmental policy

26 Cat Magazine

CONTENT_HEADING Content_Description